Thermansys equips its BOX-AM series with high-quality KANTHAL Super MoSi2 resistors, renowned for their extended lifespan even under oxidizing atmospheres. These resistors are resistant to thermal shock and capable of withstanding very high power loads, providing an efficient heating solution for rapid temperature ramping processes. They can be used continuously or intermittently without restrictions.

Chamber Furnace is a broad family of electrically heated high temperature devices that have a cubic shape heating zone.

Chamber Furnace is a broad family of electrically heated high temperature devices that have a cubic shape heating zone.

Also known as muffles, kilns and box type furnaces these devices have numerous applications including metals melting, organics combustion, ashing and ceramics sintering, chamber furnaces present necessary tools for research laboratories as also every-day partners for professionals working in ceramics, dental, jewelry or other similar areas.

Usually Chamber Furnaces have a front loading port allowing furnace loading with the subject to be treated. Lift up door design instead of traditional side hinged constructions keep hot surfaces away from operator when door is opened while chamber is hot.

Thermansys have a broad range of Chamber type Furnaces for applications requiring treatment from 1200 to 1800C operation temperature utilizing three types of heating elements that define their maximum operation temperature. Thermansys provide Chamber Furnace solutions with all possible heating elements and maximum operation temperature from 1200C to 1800C. Custom Design models are also available.

Metallic heating element furnaces is the most common type and the maximum operation temperature is restricted to 1200C-1250C continuously.

From this temperature limit and above ceramic heaters are used. For levels up to 1550C continuously, Silicon Carbide (SiC) heaters Chamber Furnaces are an excellent high value to cost option. For temperature levels of 1600C to 1800C Molybdenum Disilicide (MoSi2) heaters can only be used.

The main issues that should be considered are obviously the maximum operation temperature and the volume of the device that should be adequate to handle the desired process.

High temperature electric furnaces are in general terms expensive equipment. The potential user should be aware, when selecting a Furnace, that up to 1200C maximum operation temperature the cost of the equipment is relatively low. These models are using metallic FeCrAl heating elements (heaters). From 1200C however and above there is a non linear (step) increase on the cost of the equipment since models from 1200C maximum operation temperature and above are using ceramic heating elements and special high Alumina insulation. The user should take this cost factor under consideration when selecting a maximum operation temperature for a chamber type furnace. Even so there are users preferring to select a furnace with higher operation temperature than that is needed for his application to be used for future applications. It is important however the user to take under consideration that MoSi2 heaters furnaces for example are designed to operate from 1000C and above. It is not recommended to operate a MoSi2 furnace under 1000C for long period. The protective oxide layer of the element is reduced and the element is exposed to corrosion. The same will happen when operating the furnace with protective inert gas. Thermansys suggest a blank operation under air atmosphere above 1400C for 2 hours each time the furnace operates under reduced conditions or bellow 1000C for 24 hour or more.

High temperature environments are highly reactive. Many sub presses could run in parallel inside a high temperature furnace operating with a specific load. Usually in Chamber type Furnaces internal insulation as also the heaters are in direct contact with the process. Fluent gases as also vapors that could be produced from the processes can react with the chamber internal insulation or the heaters. Even inert gases used as protective atmosphere could produce a risk of heaters damage as indicated above. Thus special attention should be given to this point in order to avoid equipment wear or even damage. Thermansys operators manuals contain tables with maximum permissible Furnace Temperatures for various atmospheres that could be created inside the chamber of each model. The contact of the treated load samples with the insulation is also an important factor to be considered. High Alumina insulation usually used is quite inert and do not easily react with other solid material but there are exceptions. Classic example is Yttria Stabilized Zirconia that is highly reactive with fibrous Alumina insulation of the furnaces above 1500C. Please contact Thermansys Technical Team for any further assistance on this issue.

Usually due to high temperature, and the need to freely radiate, heating elements are exposed inside the heated chamber of the furnace. Special models however are available form Thermansys, like BOX-CW-1100 series and Cuppellation furnaces (CUP-AS-1200) where the heaters are protected from the processes atmosphere.

From the other hand the selection of the furnace can also be important for the quality of the treated samples. Heating elements under operation produce small quantity vapors that even extremely low could be important for the sample quality. Top example is Yttria Stabilized Zirconia Sintering. When treated uncovered inside a MoSi2 elements furnace, heaters vapors can react with the under sintering material and affect the final color and translucency. These can be avoided using a SiC heaters furnace where this effect will not take place.

Special construction with bottom loading chamber furnaces allows loading the treated subject to the bottom part (heart) of the heated zone. Either the bottom or the furnace body are moved.

Special construction with bottom loading chamber furnaces allows loading the treated subject to the bottom part (heart) of the heated zone. Either the bottom or the furnace body are moved.

Bottom loaded heated zone is permanently closed from all sides and top. This gives a big advantage to such design since resistors may exists to all four sides of the chamber leading to higher temperature uniformity. Thermal losses to the environment are also reduced compared with a front loaded furnace during operation. Bottom leaders also serves better with applications requiring loading of a hot furnace. Heat naturally goes up due to natural convention and thus opening the bottom part of the hot zone minimize losses and possible operator safety hazard compared with front loading chamber furnaces.

Thermansys can provide custom designed bottom loading furnaces on request for applications from 1200 to 1700C maximum operation temperature.

Most of Chamber type Furnaces have a chimney on the top in order to exhaust gases produced during heat treatment. Depending on application type and intense exhausted hot gases should be safely removed from the laboratory space.

Most of Chamber type Furnaces have a chimney on the top in order to exhaust gases produced during heat treatment. Depending on application type and intense exhausted hot gases should be safely removed from the laboratory space.

In case room ventilation is insufficient to carry off exhaust heat and gases which could be produced during operation the furnace should be placed under a fume hood.

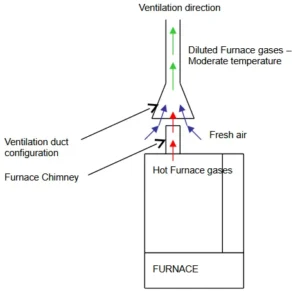

If this is also not applicable the user could also provide individual ventilation to the furnace chimney using the technique described in Figure to the right. Please note that exhaust gases exiting the chimney could have extremely high temperature. Therefore direct connection with a ventilation tubing manifold is not possible. Hot gases exiting the furnace chimney should diluted with fresh air from the environment before entering the ventilation duct lowering the overall temperature and exhausted gas species concentration.

In standard available Chamber Furnaces temperature uniformity is guaranteed as a deviation from a specific operation temperature, for a specific volume inside the hot zone, when an empty furnace is at a steady state for a specific period. Special calibration services should performed by the user to define the temperature uniformity using available international standards. This calibrations usually are involving a portion of the total furnace volume called work space. Thermansys standard furnaces are not calibrated upon delivery. This is a special service offere on request.

Generally actual temperature uniformity inside a chamber electric laboratory furnace is depended on many parameters. First of all on the operation temperature in relation with the maximum operation temperature. High temperature furnaces are designed to operate and perform better at high temperatures close to their maximum operation temperature. For a furnace with a closed sealed door the heat is transferred mainly by IR radiation generated from the heaters. Depending on the heater and on the process radiation starts to appear from 500-600C and above. Bellow this temperature limit, usually, the temperature uniformity inside the chamber is poor due to lack of a strong transferring mechanism. The higher the temperature the higher the radiation and thus proportionally temperature uniformity is improved and reach its maximum. As it can be understood since radiation is the mean for heat transfer from the heaters to the load, the load emissivity, meaning the ability of the load to absorb heat radiation, is a crucial parameter that finally will define the actual difference, if any between the furnace and the load temperature. The load type, species, geometry and mass also plays a role on the uniformity of its temperature. As a rule of thump, the higher the mass and volume and the lower the emissivity of a treated load the higher should be the dwell time for a uniform thermal treatment.

In practice, chamber furnaces are never gas tight. Given the fact that these devices usually have a chimney to exhaust fluent gases, atmospheric air is sucked through the door interfaces due to the extremely high natural convention the high temperature creates. This could create cold areas inside the chamber as cold air inserted. The user should always check the condition of the door insulation that creates the sealing with the chamber. Poor sealing there could lead to strong cold air flow at this point which will affect strongly the uniformity.

Thermansys chamber furnaces are provided with a system of controlled preheated air concept. With adjustable air opening in the back side air is driven through closed grooves within insulation receiving heat from the hot insulation. The preheated air is then entering the chamber through multiple holes at the top front of the chamber and exiting at the back creating a smooth preheated and temperature uniform laminar air stream through the load.

Chamber Furnaces are not gas tight devices. The chamber is constructed from ceramic parts mated together quite tight but not enough to create sealing. The door of chaber furnaces is also not gas sealed. Vacuum or over pressure applications are not possible inside a standard Chamber type Furnace. Applications like these require the use of a Tube Furnace combined with appropriate Work Tube and End Gas Sealling Flanges.

Usually however a protective atmosphere is possible to maintained inside a chamber furnace. Inert, oxidizing or reduced gas is possible to continuously supply a chamber. The incoming gas will continuously displace the atmospheric air existing inside the chamber and create a selective atmosphere inside. The higher the gas flow is the higher will be the concentration of the gas and the displacement of the air. In no case however Oxygen will be totally removed.

All Thermansys chamber type models are equipped with ports for protective gas supply. Most of our models are also optionally equipped with digital flow controllers.

Thermanys, a leading technology firm, is relied upon by prestigious technical universities, research centers, and private high-tech laboratories. Our objective is to develop exceptionally reliable and cutting-edge products, prioritizing user ease-of-use as a central strategy.

Thermanys, a leading technology firm, is relied upon by prestigious technical universities, research centers, and private high-tech laboratories. Our objective is to develop exceptionally reliable and cutting-edge products, prioritizing user ease-of-use as a central strategy.