Thermansys designed the RCT-AM2-1700 and RCT-AM2-1800 tube furnace series to offer extremely rapid heating solutions, with heat-up rates as high as 50˚C per minute. Equipped with high-quality Molybdenum Disilicide (MoSi2) elements selected from the KANTHAL SUPER® heating systems program, these furnace families are ideal choices for reliable, accurate, and uniform temperature control processes up to 1700˚C or 1750˚C continuously.

A tube, or tubular, furnace is a high temperature electrically heated device having a hollow cylindrical shape heating zone. It is designed to heat a working tube that fits inside its tubular heated zone and contains the treated load.

A tube, or tubular, furnace is a high temperature electrically heated device having a hollow cylindrical shape heating zone. It is designed to heat a working tube that fits inside its tubular heated zone and contains the treated load.

Usually tube furnaces are open from both sides and the working tube is protruding from each side. Special designed tube furnaces have closed one end.

Tube Furnaces combined with an appropriate Reaction Working Tube and are suitable for controlled/modified atmosphere, continuous duty processes and applications. Main application examples are Catalytic Beds testing, Organic or Inorganic Synthesis, Purification, Annealing, Degassing, Sintering, Sublimation and many others

Tube Furnaces are available under closed or split tube design. A split Tube design, also known as hinged, has the hot zone divided into two parts and permits opening of the hot zone across its axis.

The hinged construction offers convenience to the working tube installation and setting up access and provides a solution in situations when reactor is permanently connected to the processes manifold where furnace could literately wrap around it.

Tube furnaces can have one heated or multi heated zones along their length. Each zone have ind-pended temperature feedback (thermocouple) and control system.

Tube furnaces can have one heated or multi heated zones along their length. Each zone have ind-pended temperature feedback (thermocouple) and control system.

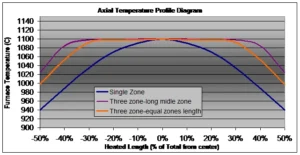

The main advantage of a multi zone tube furnace is that it increases the axial temperature uniformity. Usually a tube furnace temperature is dropping close to the two sides due to losses to the environment through the openings there. A single zone model have one heater and one temperature feedback at the middle. The controller forces the heater to keep the temperature there steady at the desired level but the actual temperature drops across furnace length as approaching the edges.

With a three zone model, having separate heated zones at the two sides with in-depended temperature feedback, the controller forces the two side heaters to give more power compared to the middle zone absorbing this way the heat losses and increasing the total uniform temperature length.

Thermansys provides as standard single zone tubular models and three zone models. Multi zone models are also available as Custom Designs.

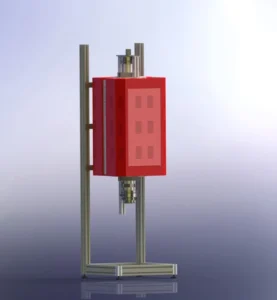

Tube furnaces can operate vertically or horizontally depending on the type and the design.

Tube furnaces can operate vertically or horizontally depending on the type and the design.

Several models have a “universal” mounting and operation design permitting the same model to operate under both conditions.

Other models however can operate either vertically or horizontally and this is an aspect that has to be decided before the purchase. Usually ultra high temperature models utilizing Molybdenum Disilicide (MoSi2) heaters cannot provide universal mounting and operation option.

Thermansys, depending on model and application, provides many options for proper reactor working tube mounting and installation on to the furnace body, as also Furnace Stands, both for horizontal and vertical operation. Consult our Technical Support team for proper working tube mounting.

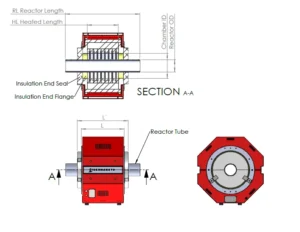

Each Tube Furnace model has a nominal diameter that corresponds to the heated cylindrical cavity. Theoretically any tube with external diameter equal or less than this diameter can be used.

Each Tube Furnace model has a nominal diameter that corresponds to the heated cylindrical cavity. Theoretically any tube with external diameter equal or less than this diameter can be used.

Usually the optimum condition is the working tube to have an external diameter at least 8-10mm less than the tube furnace diameter in order to leave some space to the heaters to radiate freely and avoid their over-heating.

Tube Furnaces, as all electrically heated high temperature furnaces, heat transport and transfer is mainly based on radiation. In the absence of forced convention, as it is the case inside a tube furnace, above 500 – 600 C, radiation is dominant compared with natural or molecular heat transfer and therefore distance of the heaters from the tube is not so important. However in order to avoid unnecessary energy losses, save initial investment and working space, the working tube diameter should be as close to this of the furnace is possible.

For applications where the working tube diameter is lower than the furnace, Thermansys provide as standard Insulation End Seals that plug and insulate both sides of the furnace tube to working tube space.

Tube Furnaces can operate utilizing three types of heating elements that define their maximum operation temperature. Thermansys provides tube furnace solutions with all possible heating elements and maximum operation temperature from 1200C to 1800C.

Metallic heating element furnaces is the most common type and their maximum operation temperature is restricted to 1200C-1250C continuously.

From this temperature limit and above ceramic heaters are used. For levels up to 1550C continuously, Silicon Carbide (SiC) heaters Tube Furnaces are an excellent high value to cost option. For temperature levels of 1600C to 1800C Molybdenum Disilicide (MoSi2) heaters can only be used.

This depends mainly on the maximum operation temperature and on application.

Metallic tubes are convenient since can be machined and weld easily proving a good solution but their usage is restricted to comparative low temperature levels. Common stainless steels can operate up to 700C while heat resistant steels are also limited close to 1000C. Special Ni alloys can operate up to 1100 -1200C continuously, while FeCrAl tubes can operate up to 1300C.

Quartz tubes are also an excellent option, especially due to the remarkable thermal shock resistance and their resistance against many atmospheres but their temperature continuous duty level goes up to 1100C.

For operation temperatures above 1100 – 1200C the most common application is high purity Alumina. Can operate up to 1700C under atmospheric pressure but suffers from very low limits of resistance against thermal shock. Mulite tubes is also a good choice for this temperature ranges.

Other possible option is Silicon Carbide for operation up to 1500C that also presents quite good thermal shock resistance.

Several restrictions however exist concerning the treated gaseous atmosphere compatibility with the tube material as also the pressure levels. Note that the pressure rating of the tube should be considered under the operation temperature which always is much lower than the rating for the same material under atmospheric temperature conditions. For example Alumina tube operation is restricted to 1420C when operating under vacuum conditions.

Thermansys provides all type of Working Tubes upon request.

Controlled and modified atmosphere conditions inside a tube furnace is created by proving sealing to both protruding sides of the working tube, or one side if the working tube have closed one end.

Controlled and modified atmosphere conditions inside a tube furnace is created by proving sealing to both protruding sides of the working tube, or one side if the working tube have closed one end.

For metallic working tubes this can be done with several ways since the material is machinable and weldable and many types of flanges or hydraulic threads can be used. Usually the proper type is application depended. Consult our Technical Support team.

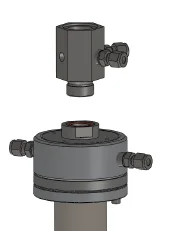

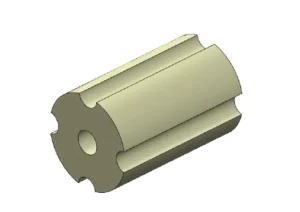

For Quartz or any kind of ceramic material working tubes special Gas End Sealing Flanges should be used. This is a compression type flange that compress an elastomeric gasket between the flange body and the tube surface providing gas seal. This flanges are metallic and have ports permitting tubing and instrumentation installation. Thermansys have many types of Gas End Sealing Flanges available and can provide Custom Designs for special application on request.

This is a complicated aspect and completely depends on the application. Many factors affect the temperature equilibrium inside a tube furnace.

First of all the tube wall is located always between the heaters and the load. For temperatures above 500C main heat transfer mechanism is radiation. Radiation generated and emitted through the heaters is absorbed from the surroundings, like the furnace insulation and the working tube, and re-emitted at different wave lengths depending on the material, its mass and its geometry. The control of the furnace is based on the heaters temperature control measured by a thermocouple probe close to the heaters. But the actual heat transfer rate to the load, end eventually its temperature, is based on radiation absorbed by the load. The radiation however absorbed by the load is a combination of all materials around it that re emit radiation at various wave lengths and the load itself properties that define which wavelengths will absorb.

Another fact is that usually tube furnace heating systems operate under control atmospheres. That means that the gas atmosphere inside the tube and around the load is dynamic. The pressure and the flow is also critical. For example high flow rates around the load will strongly affect its temperature again however depending on the gas flow temperature, the contact surface with the load, and the heat transfer properties between gas and load. Preheating of the gas flow inside a tube furnace reactor is sometimes important in order to avoid load cool down due to “cold” flow rates. Long heated zone furnaces or three zone models could help on this direction.

As a rule of thumb, in most of cases, the temperature of the load is quite different than this of the furnace during dynamic conditions like heat up. The higher the heat up rate is the higher will be this difference. Usually when the system reach a steady point, after one or two hours, this difference become smaller and for a system operating horizontally with relatively low flow rates the difference could be restricted bellow 10C. It should be noted that it is common during heat up, especially at low temperature levels, and with a transparent reactor tube like quartz the temperature inside the tube to be even higher than this of the furnace.

Thermansys Tube Furnaces power supply and control systems provide a 3 channel Thermocouple measurement board as standard. The user can connect there a Thermocouple and monitor the temperature through Pyrologism software. Usually users are using this channels to connect probes that are facing the reactor environment close to the point of interest. Pyrologism have a special feature that allows the user to use one of these channels as the control Thermocouple. This way the system “command” the heaters to regulate the temperature directly to the point of interest, absorbing and blunt the results of the above described issues. It should be noted however that this feature imply that the user have experience working with heating systems and full knowledge of its application since otherwise heaters could be over heated and damaged. The use of a Programmable Watchdog option is highly recommended for these cases.

Usually gas sealing on the working tubes of a Tube Furnace is done using compression type End Gas Sealing Flanges. These flanges are using elastomeric gaskets to seal and their temperature is restricted to 200-250C because of that. Therefore the temperature of the tube at its end should be lower than this limit. Many times it is advisable the temperature at the ends of the tube to be even lower than 80C for safety reasons since people are moving and working around it.

Usually gas sealing on the working tubes of a Tube Furnace is done using compression type End Gas Sealing Flanges. These flanges are using elastomeric gaskets to seal and their temperature is restricted to 200-250C because of that. Therefore the temperature of the tube at its end should be lower than this limit. Many times it is advisable the temperature at the ends of the tube to be even lower than 80C for safety reasons since people are moving and working around it.

The temperature at the end of the tube depends on the tube material thermal conductivity, possible gas flow rates inside the tube and the furnace orientation. It should be noted that for vertically operated furnaces natural convention inside the heated cavity is very strong due to extremely high temperatures and the upper part is suffering from excessive temperature, while the lower part is cool. The user should provide very good sealing of the free space between the tube and the furnace at both ends, using ceramic wool to avoid air sucking through the furnace cavity from bellow which eventually will exit the furnace from above and overheat the end sealing flange.

Gas flow rates are also very importation since high flow rates will transfer heat the tube and the flange downstream.

Material of the tube is also highly important. Metallic or Silicon Carbide tubes have high thermal transfer coefficient and sides are overheated due to molecular heat transfer, while from the other hand ceramics like Alumina, and especially Quartz, present low thermal transfer.

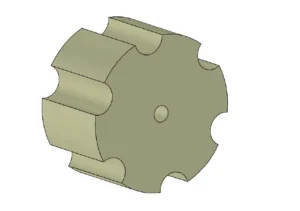

End Gas Seal Flanges temperature also raise from radiation that come from the internal of the tube. To avoid direct contact of the gas end sealing flanges with the radiation the use of Radiation Shield is highly recommended. These usually are ceramic tubular items that fit the internal diameter of the tube and are positioned inside the tube between the load and the two sides of the tube. Thermansys provide high purity crystalline dense Alumina Radiation Shields for tube diameters from 20 to 190mm. Radiation overheating of the flanges is more pronounced as the tube diameter increases. For tube diameters 60mm and above the use of Radiation Shields is highly recommended.

Thermansys Gas End Sealing Flanges are equipped as standard with a cooling shell allowing optional water to flow and cool down the flange. The use of water cooling is strongly recommended for vertical operated systems and for metallic working tubes.

Generally a protruding length of about 200-300mm is adequate for horizontal operation and moderate gas flows for ceramic and quartz tubes. Radiation shield will reduce further the flange temperature and enhance safety and energy consumption.

Thermanys, a leading technology firm, is relied upon by prestigious technical universities, research centers, and private high-tech laboratories. Our objective is to develop exceptionally reliable and cutting-edge products, prioritizing user ease-of-use as a central strategy.

Thermanys, a leading technology firm, is relied upon by prestigious technical universities, research centers, and private high-tech laboratories. Our objective is to develop exceptionally reliable and cutting-edge products, prioritizing user ease-of-use as a central strategy.